MVD (mvd)

Overview

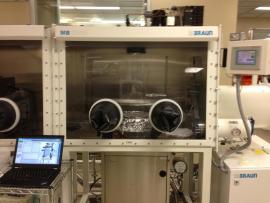

MVD is a molecular vapor deposition (MVD) system. It is a self assembling monolayers (SAMs)-based configuration of a Savannah S200 from Cambridge Nanotech with 1 SAMs delivery port and 4 standard atomic layer deposition (ALD) lines. It is used to deposit organic SAMS layers and metal oxides on 2-D materials. The system can accommodate pieces up to an 8" wafer. Many thanks to Xiaoxing Xu, Ateeq Suria, Alex Piggott, and Felix Alfonso for their contributions to this page.

Cleanliness:

Processing Technique(s)

Capabilities and Specifications

Lab Supplied Materials

Material Thickness Range: 1.0 Å - 50.0 nm

Process Temperature Range:

24 °C - 150 °C

Gases

Substrate Sizes

Notes:

Reactor located inside glovebox

Lab Organization, Location, and NEMO Information

Lab Organization:

Location:

NEMO Area:

SNF: Chemical Vapor Deposition

NEMO ID:

mvd

Training and Maintenance

Lab Facility:

Training Charges:

3.00 hours

Primary Trainer:

Backup Trainer(s):

Primary Maintenance:

Backup Maintenance:

Steps to become a tool user

-

Become a member of SNF.

- Study the relevant operating procedures:

- Shadow labmembers who are using the MVD. Make sure to ask lots of questions until you feel familiar that you could run it yourself.

- Contact the primary trainer to set up an appointment for the written quiz.

- After successfully passing the written quiz, you will set up a time for the final practical in-lab session.