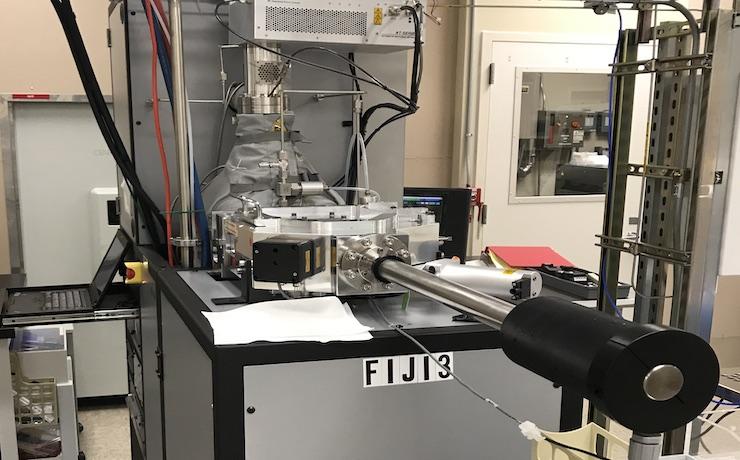

Fiji 3 ALD (fiji3)

Overview

The Fiji3 ALD system from Cambridge Nanotech/Ultratech is a plasma enabled atomic layer deposition system for deposition of restricted oxide films. The system is in the Flexible cleanliness category and allows a limited subset of gold contaminated substrates. Overall the processing is the same as Fiji2 with a couple of restrictions taken for this system based on purpose for which the system was purchased under a specific grant. These restrictions are: No pure metal or nitride depositions allowed No substrates or deposition of Zinc, Indium, Vanadium, or any of their constituent films No substrates or pieces for deposition with polymer, photoresist, or anything else that might outgas

Cleanliness:

Processing Technique(s)

Capabilities and Specifications

Lab Supplied Materials

Material Thickness Range: 1.0 Å - 50.0 nm

Process Temperature Range:

24 °C - 350 °C

Gases

Substrate Type

Substrate Sizes

Notes:

Restricted to non-conductive films only

Lab Organization, Location, and NEMO Information

Lab Organization:

Location:

NEMO Area:

SNF: Chemical Vapor Deposition

NEMO ID:

fiji3

Training and Maintenance

Lab Facility:

Training Charges:

2.00 hours

Primary Trainer:

Backup Trainer(s):

Primary Maintenance:

Backup Maintenance:

Steps to become a tool user

-

Become a member of SNF.

- You need to be qualified as an operator on Fiji1/2 with at least 10 successful operations.

- Study the relevant operating procedures:

- Shadow another labmember who is using Fiji3.

- Contact the primary trainer to take the short written quiz for the Fiji3. The quiz is closed book and all the information should be known to a someone who has studied the online documentation and has successfully used Fiji1/2.

- Oral Qualification Exam. After the written quiz has been passed, you may schedule a final oral qualification exam with trainer. At this exam you are expected to demonstrate your ability to run the tool safely and appropriately without any input.