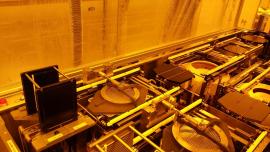

SVG Resist Coat Track 2 (svgcoat2)

Overview

The SVG (Silicon Valley Group) coater is an automated track system for dispensing photoresist on 4" silicon, glass, or quartz wafers. The system includes two stations: a prime oven which bakes the wafer and dispenses the adhesion promoter, HMDS; and a combination spinner, which dispenses photoresist, and pre-bake oven which cures the resist. HMDS is only available at track 2. The uniformity of spun photoresists are typically +/- 100 Å.

Cleanliness:

Processing Technique(s)

Capabilities and Specifications

Lithography Specifications

Substrate Type

Substrate Sizes

Maximum Load:

25 4 inch wafers

Notes:

Automatic HMDS, Resist spinning, and Bake. AZ5214IR Image Reversal.

Lab Organization, Location, and NEMO Information

Lab Organization:

Location:

NEMO Area:

SNF: Photolithography

NEMO ID:

svgcoat2

Training and Maintenance

Lab Facility:

Training Charges:

1.25 hours

Primary Trainer:

Backup Trainer(s):

Primary Maintenance:

Backup Maintenance:

Steps to become a tool user

-

Become a member of SNF.

- "All Litho" class is required before training on any of the lithography tools. Please send an email to all-litho-training@lists.stanford.edu to sign up for the All Litho class. Read more here: All Litho class.

- Study the relevant operating procedures:

- Shadowing is required. Contact a qualified lab member of the tool to arrange to ‘shadow’. It would be best to find someone who has used the system often. If you don’t know of anyone, you may check reservations or history to find a qualified user. We recommend that you be with the lab member for the full time while operating the tool and ask lots of questions during the shadowing. You may have to shadow a qualified user more than one time to be comfortable with the tool. Please follow the instructions on this form: Shadowing at SNF

- During shadowing, use this SVG coat check list.

- Contact the primary trainer: Uli Thumser