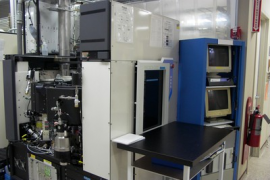

AMAT P5000 Etcher (p5000etch)

Overview

P5000 is a load-locked, magnetically enhanced reactive ion etching system (MERIE) with two functional process chambers (Chambers B & C). P5000 Chamber B is primarily used for etching silicon based dielectrics (silicon dioxide, silcon nitride, etc.) and some carbon based compounds (resist, poly imide, etc) while chamber C is ainly uused for silicon etching with high slectivity to underlying dielectric such as silicon dioxide. The system can process only 4" wafers. Pieces have to be attached to a 4" wafer. Though the process chamber processes one wafer at a time, upto 25 wafers can be loaded per batch. Note that transparent wafers can not be loaded in the automatic processing mode. P5000 is currently classified as CMOS restricted. Chamber A - Metal Etch Chamber - Not working Chamber B - Oxide Etch Chamber Chamber C - Poly Etch Chamber Note that all gases are not connected to all the chambers. For details refer to the operating instructions.

Cleanliness:

Processing Technique(s)

Capabilities and Specifications

Primary Materials Etched

Other Materials Etched

Gases

Lab Organization, Location, and NEMO Information

Lab Organization:

Location:

NEMO Area:

SNF: Dry Etching

NEMO ID:

p5000etch

Training and Maintenance

Lab Facility:

Training Charges:

1.00 hours

Primary Trainer:

Primary Maintenance:

Backup Maintenance:

Steps to become a tool user

-

Become a member of SNF.

- (No information provided. Please inform the Primary Trainer or another member of staff.)

- The following step Online Course is optional:

- Online Course for general information about the online training. Go to Online Nano Course Login to log in directly to the course.

Go to "nano@stanford" and then to the "Dry Etching" section for the three videos on plasma etching principles and to "Choosing a Dry Etching Process" section for guidelines for choosing the right equipment. - Shadowing is required. Contact a qualified lab member of the tool to arrange to ‘shadow’. It would be best to find someone who has used the system often. If you don’t know of anyone, you may check reservations or history to find a qualified user. We recommend that you be with the lab member for the full time while operating the tool and ask lots of questions during the shadowing. You may have to shadow a qualified user more than one time to be comfortable with the tool. Please follow the instructions on this form: Shadowing at SNF

- Contact the primary trainer: Lavendra Mandyam